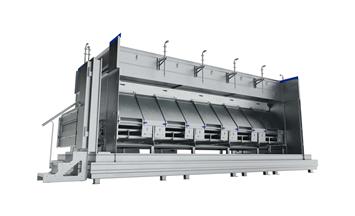

Mechanical tunnel freezers and cookers

IQF tunnel systems are ideal for freezing, cooling, and heating quality food.

This is a method to preserve the freshness and natural appearance of your frozen food while increasing your profitability. All of our IQF tunnel freezers and cookers are designed to minimize the cost per product, ensure a low energy consumption, and guarantee the maximum yield. Together, these factors add up to ensure high product quality, energy efficiency, and food safety.

Tunnel freezing and heating is characterized by conveying food through a tunnel of circulating cold air to freeze it very fast and homogeneously. It is rapid, efficient, and gentle – and it has a minimal effect on the cell structure. This results in improved food quality and a high yield with only 0.2% drip loss depending on your product.

Our special design ensures easy cleaning, maintenance, and a long service life. We only use high quality stainless steel components to meet even the strictest cleaning requirements and avoid corrosion.

Our IQF tunnel solutions are always based on your product characteristics, capacities, facility space, and line layout. And you can count on our contribution to secure you a suitable solution that guarantees the homogeneous and precise thermal treatment of your food.

Tunnel freezers and cookers are suited for deep freezing as well as crust freezing and thermal treatment of standard as well as fragile food – but we also develop specialized niche products such as equipment to treat glazed food.