IQF spiral freezing, cooling, and heating

Spiral IQF solutions designed to minimize the cost per kg treated product, ensure a low energy consumption, and guarantee the maximum yield.

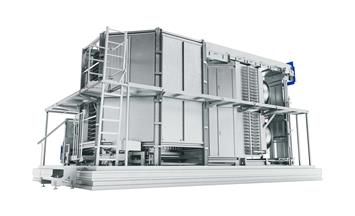

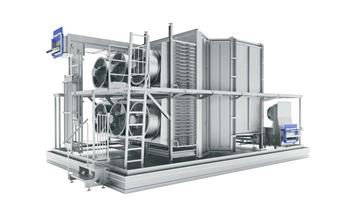

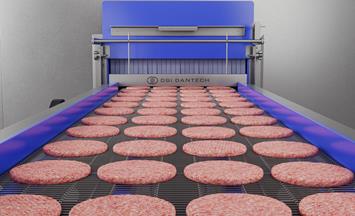

IQF spiral freezers are ideal for freezing, chilling, and heating quality food, such as fish, shrimp, meat, poultry, berries, fruits, and vegetables as well as pasta, cheese, baked goods, and grains. All our IQF spiral systems are designed to minimize the cost per kg treated product, ensure a low energy consumption, and guarantee the maximum yield. Together, these factors add up to ensure a small carbon footprint in your production.

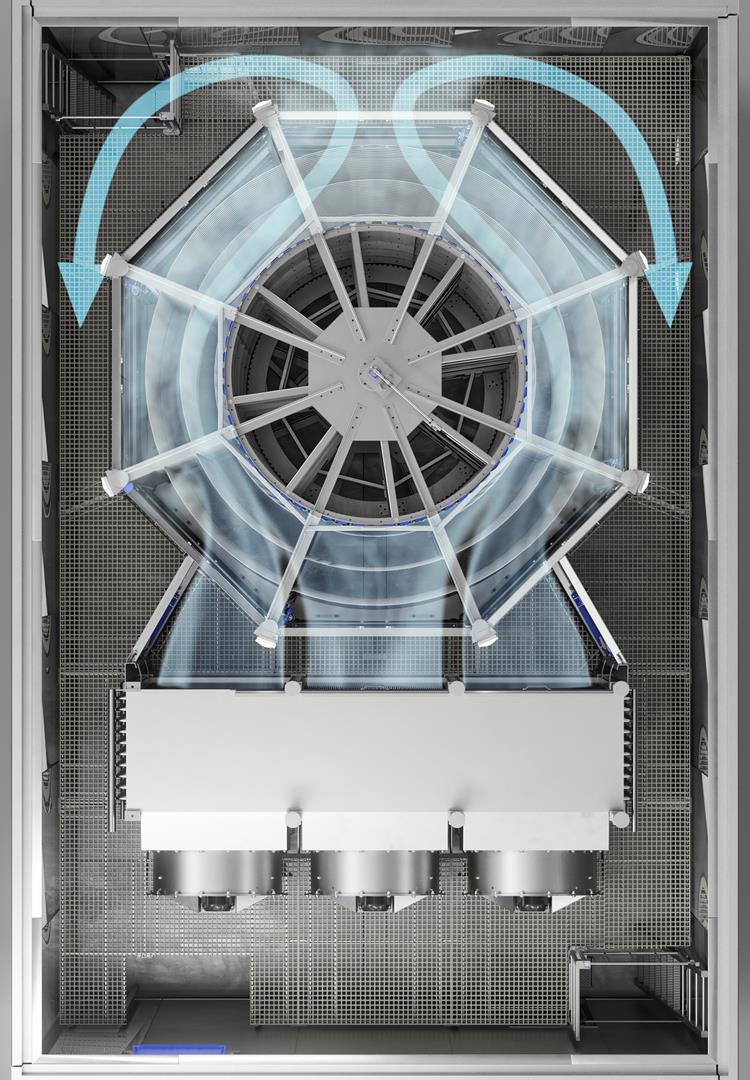

IQF spiral technology is characterized by transporting food products around a rotating drum on a conveyer belt using the principle of fast and cold air circulation that flows horizontally and is guided over the product. Our unique and efficient airflow results in faster freezing times, less product dehydration, and higher quality and yield. On top of that, our spirals can run hot breaded and fried products for 144 hours without defrost and sequential defrost. This minimizes bacteria growth and maximizes food safety.

Our spiral solutions are always based on your product characteristics, capacities, facility space, and line layout. You can count on our contribution to secure you a suitable solution that guarantees you homogeneous and precise thermal treatment of your food.

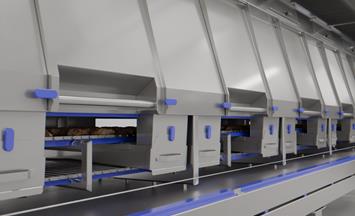

The spirals have a compact and open design for easy cleaning and maintenance as well as a long service life. We only use high-quality stainless-steel components to meet even the strictest cleaning requirements and avoid corrosion. The belts are compact and capable of freezing large amounts of products with longer dwell times; this makes the technology one of the most preferred food processes in the industry.

Our range of spiral machinery covers spiral freezers, spiral ovens, spiral sous vide, spiral pasteurizers, spiral proofers, and spiral conditioners.