Freezers for vertical block freezing

Vertical plate freezers are ideal for freezing large volumes of food and liquids very quickly to sustain the food quality and ensure food safety.

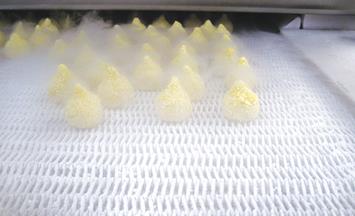

The vertical plate freezers are designed to block freeze food without or with little pre-handling directly on site. It is suitable for products such as fish, shellfish, meat and poultry, vegetables, fruits, liquids, by-products, and offal for pet food.

The freezing process is based on double contact freezing, and the method is 30% faster than the traditional blast freezing solutions. Our freezers are designed for the fast, economical freezing of large quantities while ensuring high product quality and the preservation of taste, texture, and nutritional value. With more than 10,000 installations worldwide, our plate freezing solutions are the preferred and trusted solutions across the market.

We offer four series of freezers with characteristic functionalities. Each freezer is specially designed to fit your capacity in terms of space on the production site as well as the preferred batch weight or block size.